Front:

11

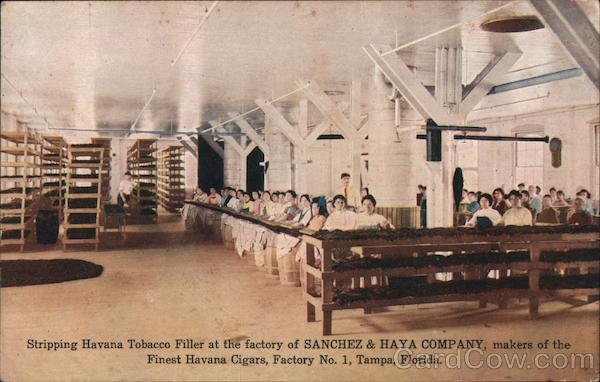

Stripping Havana Tobacco Filler at the factory of SANCHEZ & HAYA COMPANY, makers of the

Finest Havana Cigars, Factory No. 1, Tampa, Florida.

Back:

This particular work is always done by

women. After the tobacco filler is stripped it

is kept on racks in small bunches until it gets

in condition to be transferred to barrels.

Great care is taken not to mix the different

grades of tobacco while it is on the racks and

also when transferred to barrels. Once the

filler is put in barrels they are taken to a large

room situated in this department, which can

be seen in this picture back of the strippers.

Here also the different grades of tobacco are

separated and each barrel bears the name of

the plantation in Cuba where the tobacco was

grown, the year's crops, the date tobacco was

stripped, and also the grade of the tobacco.

It is impossible to state how long the to-

bacco must be kept in the barrels before using.

It takes from three weeks up to eight months,

or more, depending entirely upon how long a

time the leaf requires to be properly cured.

Nothing must be done to rush the curing pro-

The tobacco itself must get to that

point where it is in condition to be turned

into cigars.

cess.

The next stage of high-grade manufact-

uring Havana Tobacco is the blending, as

shown on card No. 9.

CARD NO. 8

35

OSTCARD

DOST

SIMPLICITY

GRAND

RAPIDS

THIS SPACE FOR ADDRESS ONLY